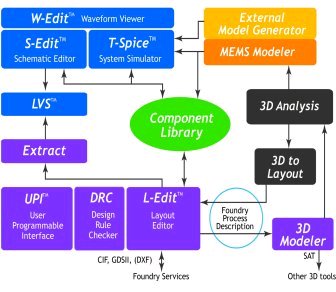

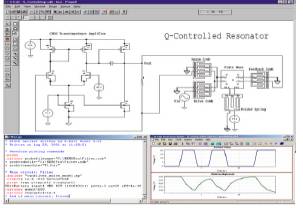

MEMS Pro v6.0 is a flexible, powerful, easy-to-use CAD tool suite for the design and analysis of micro-electro-mechanical systems (MEMS). It offers an integrated solution for the design process that shortens development time while providing designers reliable analysis for manufacture. Functionalities include mixed MEMS/IC schematic capture and simulation, full custom mask layout capability and verification, 3D model generation and visualization, behavioral model creation and links to 3D analysis packages.

Try MEMS Pro v6.0 for 30 Days

Download the DATA SHEET and CONFIGURATIONS document in .pdf format.

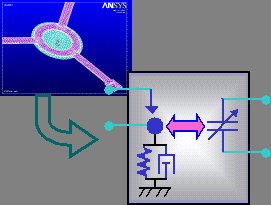

Modeling Tools: MEMS Modeler automatically generates behavioral models ready for system simulation with electronics and packaging from 3D data from analysis packages. Complex, finite element models involving a large number of degrees of freedom are reduced to a few master degrees of freedom. Users can also create their own models from analytical equations and the tool generates simulation-ready descriptions in a variety of popular formats.

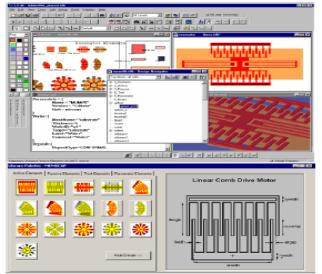

Layout

Editing: MEMS Pro v6.0’s

physical design environment includes a fully hierarchical and full

custom editor engineered for MEMS and IC design. The program uses an

intuitive interface and provides specific MEMS-related capabilities

that greatly reduce layout time. It provides all-angle support. A curve

generator allows designers to create MEMS primitives, such as torii,

splines, fillets and general equation-based curves. The EasyMEMS tool helps to

automate tasks that are time-consuming for creating MEMS mask layout

such as creating polar arrays. Useful macros include the generation of

holes and dimples to properly release MEMS structures. A

powerful interface is included for automating, customizing and

extending the layout editor command and function set using the C

language. Popular output formats are supported so mask designs are

“foundry ready”.

MEMS

Verification provides

a configurable design rule checker that verifies MEMS layout against

fabrication requirements to prevent costly design errors causing extra

fabrication runs and ensures manufacturability. In addition,

application and device specific context sensitive rule

checking is included. An Extractor generates a SPICE netlist

from a MEMS layout including MEMS devices, their parameters and

multi-domain connectivity. The LVS (Layout vs. Schematic) tool

takes the extracted data and compares it against the SPICE netlist from

the schematic editor to ensure that the mask layout captures the

designer’s intent.

The 3D Solid Modeler creates a 3D view of a MEMS device from the device layout and

fabrication process description. An easy to use GUI permits designers

to enter fabrication process steps and sequences. Surface and bulk

micromachining process steps such as material deposit, etch, mechanical

polish, diffusion, growth, electroplating and wafer manipulation steps

are supported. The 3D model may be scaled and a subset of mask layers

may be selected for view. Models can be viewed with rotations, zooms,

and preset views. The Cross

Section Viewer displays a cutaway view in the z-dimension

based on a user-specified cut line. As MEMS are inherently 3D

structures use of these tools is important to understand the resulting

fabricated device structure in 3D dimensions. 3D-To-Layout converts

3D solid models into 2D mask layouts using user-specified fabrication

process descriptions, enabling capture of device mask modifications

made in 3D analysis programs.

Foundry Modules enable targeting of specific process technologies and provide process-specific device intellectual property. A variety of foundry-specific modules are fully integrated with SoftMEMS’ tool suites to ensure process compatibility and manufacturability with the world’s leading MEMS foundries. Foundry modules include design rules, mask layer descriptions, device descriptions for extraction, process parameters and material properties, and fabrication process descriptions.